1、 Basic information:

Due to the dispersed geographical location of urban heating, stable acquisition and control functions and high safety requirements, the heating dispatching department needs to centrally and real-time monitor the temperature, pressure, flow and other parameters scattered in different geographical locations in the heat exchange station to control the operation of each equipment in the heat exchange station. At the same time, the operating conditions of the thermal power plant are adjusted according to the operating parameters of each heat exchange station monitored from the site to ensure the stable operation of the whole heating in winter.

The current operation and management of thermal power stations in China is still in the stage of manual operation, which affects the full play of the advantages of central heating. Mainly reflected in: lack of comprehensive parameter measurement means, unable to systematically analyze and judge the operating conditions; The maladjustment of system operation conditions is difficult to eliminate, resulting in uneven cooling and heating of users; The heating parameters fail to operate under the best working conditions, and the heating capacity does not match the heat demand; Incomplete operation data makes it difficult to realize quantitative management. To do a good job in urban central heating projects, we must comprehensively improve the level of heating technology.

2、 System scheme:

2.1 system overview:

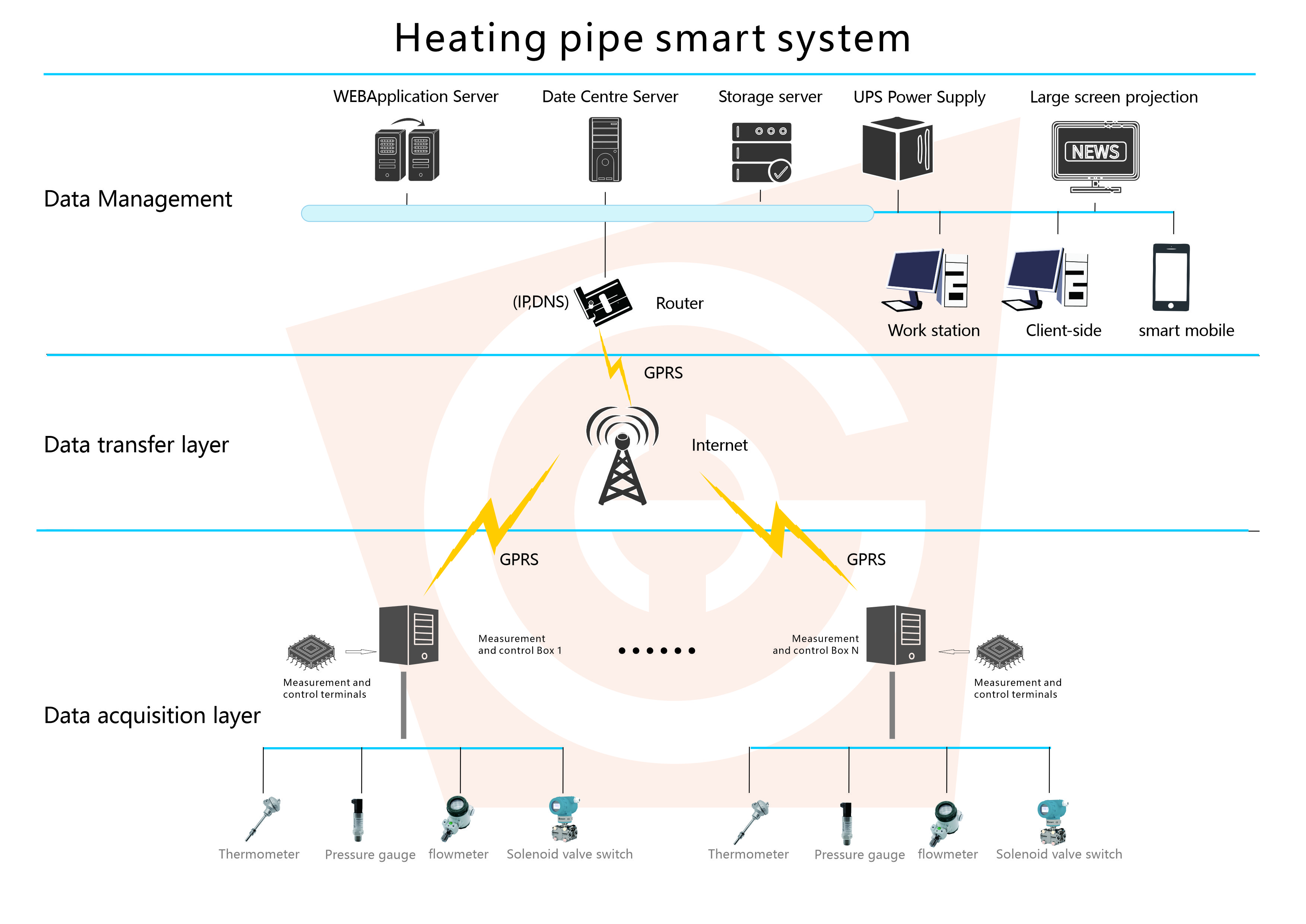

The wireless monitoring and management system of urban heating pipe network completes the monitoring, summary, conversion and transmission of the content of monitoring factors, including temperature, pressure and flow. These monitoring factors are measured by the measurement and control terminal using different methods to obtain a very accurate measurement data, This result transmits data to the monitoring center through GPRS network after data processing and conversion. The monitoring center realizes the tasks of data receiving, filtering, storage, processing, statistical analysis and providing real-time data query. When the temperature or pressure exceeds the set value, the designated equipment will be automatically opened or closed. The whole system can achieve: safe, reliable, accurate, real-time, comprehensive, fast and efficient display the real urban heating pipe network information in front of managers.

2.2 system composition:

2.21 data management (monitoring center):

The hardware mainly includes: workstation computer and server (fixed IP dedicated line or dynamic IP domain name mode of Telecom, China Mobile or China Unicom);

The software mainly includes: operating system software, data center software, database software, heating pipe network remote intelligent monitoring system software platform (B / S structure is adopted, which can support browsing and viewing in WAN), firewall software;

2.22 data transmission layer (data communication network):

GPRS network of mobile company is adopted to transmit data. The system does not need wiring, and the construction is simple, fast and stable;

Mobile wireless networking mode has the characteristics of high data transmission rate, wide signal coverage, strong real-time performance, high security, low operation cost and low maintenance cost;

2.23. Data acquisition layer (front-end hardware equipment):

Complete set of remote measurement and control equipment: Measurement and control terminal;

Sensing and metering equipment: pressure sensor, temperature sensor, flowmeter and solenoid valve;

2.3. System topology:

3、 System functions:

01. Acquisition function:

Pipeline flow: instantaneous flow;

Pipeline flow: cumulative flow;

Pipeline pressure: pressure value;

Pipe temperature: temperature value;

02. Alarm function:

Power failure alarm, pressure, temperature, flow fault alarm, measurement and control terminal alarm;

Status change alarm prompt: alarm status change. If the pressure suddenly increases or decreases;

03. Storage function:

Pressure, temperature, flow information, real-time data, event records and operation records are stored in the database;

04. Query function:

Pressure, temperature, flow information, historical records, historical curves, event records, operation records and historical reports;

05. Statistical function:

Report function: daily report, monthly report and annual report;

Curve function: daily curve, monthly curve and annual curve;

06. Printing function:

Pressure, temperature, flow information, historical records, historical curves, event records, operation records and reports;

07. Safety function:

Password function: you must enter a password to enter the system;

Permission function: different operators have different functions;

User switching: different operators can switch in the system during handover;

08. Extended functions:

Pressure, temperature, flow quantity: users can add or delete sites.

Remote control: when adding solenoid valve, it can output the opening of remote control valve;

09. Setting function:

Site information input and modification;

Collection cycle setting and modification;

10. Remote maintenance function:

Remotely set the working parameters of the station (pressure, temperature and flow);

4、 System features:

01. Practicability: urban heating stations are geographically dispersed, so GPRS network with wide coverage is used for high signal capture. It is necessary to use high gain antenna to ensure the normal operation of the network;

02. Real time: using the latest communication and software and hardware technology, a clear and reasonable system architecture is established, which can realize multi-threaded remote concurrent communication. In a few seconds, hundreds of measurement and control terminals can be transmitted to the monitoring center in real time for centralized monitoring and remote scheduling, so as to realize the timely alarm of fault information;

03. Expandability: the system reserves interfaces, which can carry out unlimited expansion of the system or software and hardware modules, facilitate long-term upgrading and maintenance, and prolong the service life of the system. By updating components, the system can exist all the time without paralysis of the whole system, resulting in a large amount of investment loss;

04. Maintainability: the system can execute corresponding remote operation commands for the measurement and control terminal, including remote parameter setting, remote control, remote data reading, remote terminal reset, remote measurement and control terminal upgrade, etc;

05. Ease of operation: the system software has perfect functions, modular and graphical design, Chinese help in the whole process, and simple and convenient operation;

Technical Introduction: Graeff's High Temperature Melt...

2022-07-01Application of Graeff sensor in remote intelligent monitoring system of urban heating pipe network

2021-11-29Technical Introduction: Graeff's Temperature Sensor

2022-07-01Technical Introduction: Graeff's Intelligent and Industrial Sensor

2022-07-01Chinaplas 2022 is cancelled in Shanghai, and will be available...

2022-04-25EXHIBITION PREVIEW | ARABPLAST

2022-12-29EXHIBITION PREVIEW | PLAST EURASIA

2022-12-29EXHIBITION PREVIEW | PLASTIMAGEN

2022-12-29EXHIBITION PREVIEW | South Africa International Plastic Food Packaging and Printing Industry Exhibition

2022-12-29EXHIBITION PREVIEW | Vietnamplas

2022-12-29